Create

Model

Build

We design carpentry solutions tailored to your needs, managing every phase internally – from design to post-sale support – integrating skills from our entire team. This allows us to create customised products with high levels of precision and resistance. We are a unique, reliable and structured partner.

ERP and MES

management

software

We use ERP and MES systems to coordinate and optimise all company activities. The ERP system helps us manage logistics, while the MES system monitors production in real time. This approach enhances operational efficiency and ensures quality control throughout every stage of production.

Full CAD/CAM integration

Traceability of materials and processes

Activity organisation

Quality control

Custom

production

We handle each step of the production process internally from design to post-sale support, we develop tailored and flexible solutions to meet various sector needs. Production is carried out to high standards ensuring precision, consistency and reliability.

-

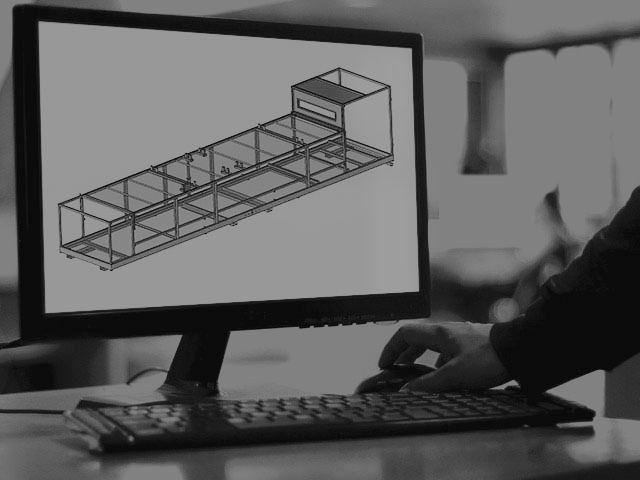

Design

Custom technical design

We develop construction drawings starting from layouts, preliminary studies or prototypes provided by the client. We can also design based on simple guidelines, sharing each phase of the process with the managers of the various areas involved.

-

Welding

Certified UNI-EN and ASME – MIG / TIG / electrode

We perform MIG/MAG/TIG and electrode welding on standard and special steels. Every phase is handled by qualified operators and supervised by a department manager, ensuring uniformity, strength and structural precision.

-

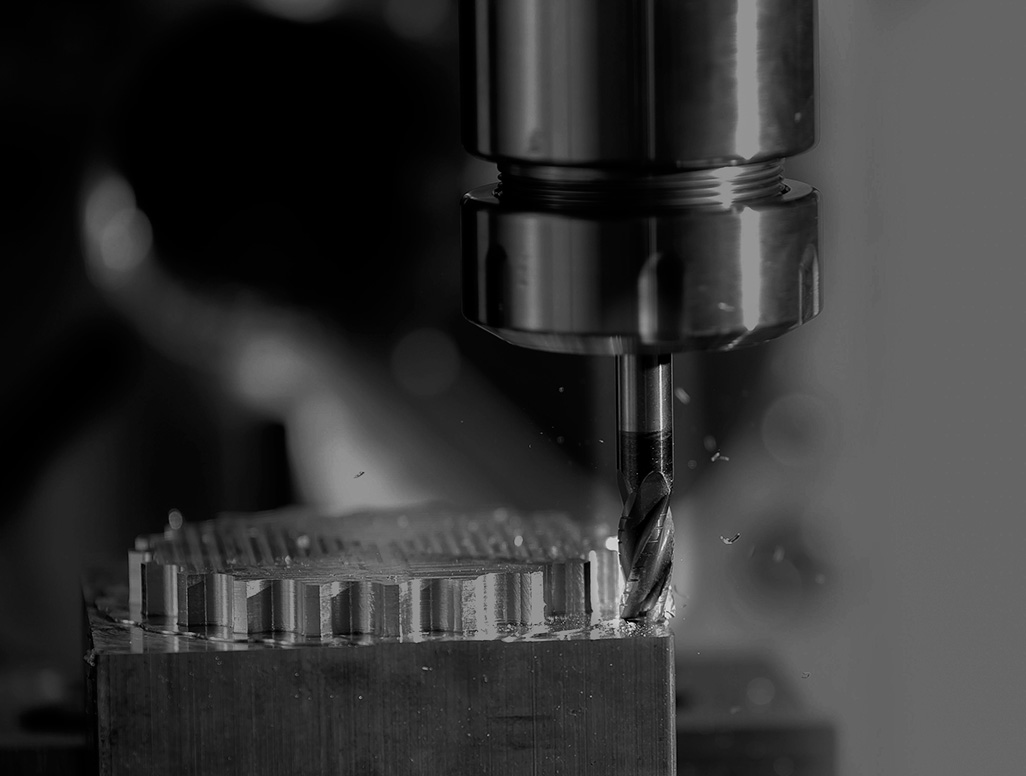

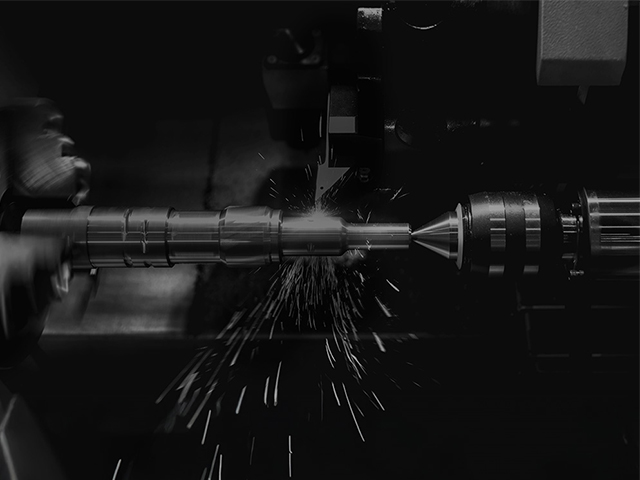

Mechanical processing

Milling, boring and turning for all metal structures

We carry out mechanical processing such as milling, boring and turning on all metal structures. Every operation is aimed at ensuring precise finishes, high mechanical performance, and long-lasting aesthetic quality.

-

Laser cutting

Fiber laser with automatic magazine

We specialise in high-precision laser cutting using advanced, next-generation automation. We work with materials of various thicknesses and geometries, ensuring speed, consistent quality and full traceability.

-

Bending

Latest generation bending machines with 3D CAM software

We perform metal and metal sheet bending using advanced technology systems. The use of 3D CAM software allows us to program and simulate each bend with precision, optimising both time and quality of results. We process materials such as stainless steel AISI 304, AISI 316, and special steels.

-

In-house painting

Filing, sanding, solvent-based and water-based coating

We manage all stages of liquid painting in-house, both solvent-based and water-based. We offer customisation of processing cycles according to specific technical requirements or based on established standards.

We use high-quality paints selected according to the operating environment. We also carry out painting interventions on complex machinery and retrofitting of existing systems, combining aesthetics and functionality.

-

Surface treatments

Galvanising,, bluing, powder coating, thermal stress relief, and much more

We apply technical and functional surface treatments such as galvanising, bluing, powder coating, and thermal stress relief. Each treatment is designed to improve the products performance, enhancing its appearance, durability and resistance according to specific usage requirements.

-

Mechanical assembly

Mechanical assembly , functional testing and final inspection

We handle in-house mechanical assembly on machines and metal structures, including functional tests and final inspections.

We also perform on-site assembly directly at the customer’s location, using qualified and well-equipped personnel, ensuring fast, coordinated and professional operations.

Operational

sectors

AUTOMATION AND ROBOTICS

Robotics integrators

Machine tools

Automatic machines

INDUSTRIAL MACHINERY

Transfer machines

Aluminium extrusion systems

Steel production systems

Hydraulic systems

ENERGY AND ENVIRONMENT

Lifting Machinery

Cogeneration systems and equipment

Waste treatment and recycling systems